Post press

Post press is the last step in the production of each publication, which creates personality and gives the final look.

Post press processing gives the publication exactly the design you need:

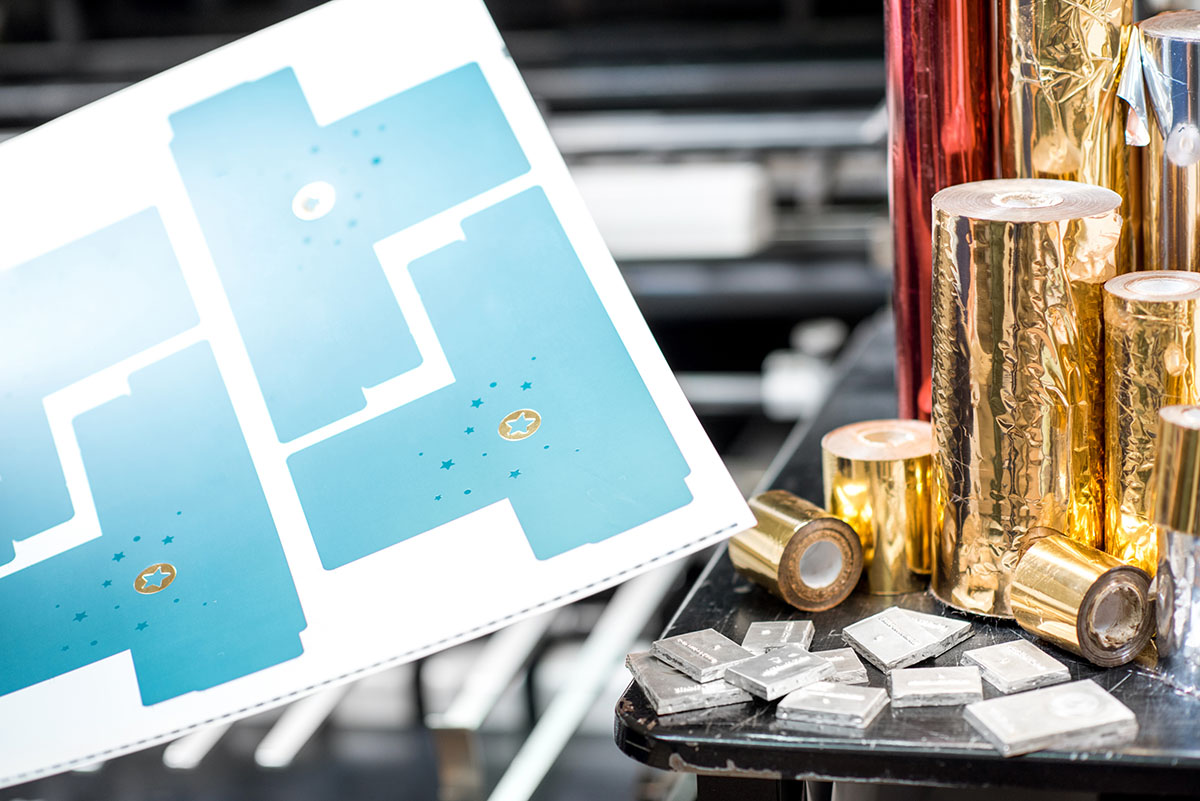

die-cutting

means the process by which the surface of a package is pushed out of the sheet, the edges and corners being grooved.

foil printing

speciality printing process which uses heat, pressure and metallic paper (foil). This is used to create different shiny designs and graphics on various materials. Foil printing gives the focus area an incredible look and is quickly becoming the preferred method of printing in many industries.

embossing and debossing

embossing is an image pressed outwards on the surface of paper or cardboard, while debossing is, on the contrary, an image pressed inwards. For example, braille text is also embossing, for example printed on pharmaceutical packages.

all-over UV varnish

allows to cover the whole package evenly with either glossy or matt varnish (results are very different)

UV spot varnish

allows you to highlight a specific design element

grooving

simplifies folding

folding

folded printing is more compact and convenient to carry

cut

gives the print a straight edge or creates just the shape you want

drilling

making holes (eg for hanging a print or putting it in a binder)

gluing

joining pages (eg to create a logical sequence)

perforation

means the creation of a dotted line on a print to make it easier to break (eg to create windows in an Advent calendar)

numbering

ensures a logical sequence and saves the user time

wiring

means the fixing of sheets of paper by wire

binding

various techniques can be used, such as gluing, saddle-stitching or wire-o binding